yeah man, the old transformer machines were monsters but the new inverter machines are awesome. I'm really loving my dynasty 200, but as I'm using it more & more I can see how a dynasty 350 would be the ultimate machine to have, but the 200 is really more than enough most of the time, if you want a nice compact top of the line tig it's hard to beat.

update? well, I've been practicing & practicing, but I've also had some problems along the way... the cold saw started to crap out & I had to wait for some parts which sucked up a few weeks down time, then I had to redo the whole fluid pumping setup again & built a custom stand to make it 100% contain the fluid without making a mess... working at home is not the same as working at the shop where mess & noise are a non issue

in the mean time I decided that my whole home garage workshop area was crap. one problem is, up until now I've only got one 15 amp 120v feed to the garage, AND the same circuit also fed my upstairs living room entertainment center too, so whenever I forgot to turn the heat off & started to tig the breaker would trip, sometimes just the startup of the compressor or my vacuum pump would even trip the breaker. breaker trips always lead to the same thing, try to find my way through the hallway to the panel in the dark, then wind up with all the clocks in all the entertainment & tv setup returning to blinking 12:00, this gets old pretty quick so I finally decided to get my electrician out to the house to see what can be done to add a new feed to the garage...

long story short this prompted me installing a new 100 amp 3 phase sub panel in my garage & completely redoing all new electrical & then redoing the whole garage itself, ripped all the old shelving & workbench & everything out & replaced everything, got a nice craftsman stainless steel worktop bench & kinda reorganized everything to make a better fabrication shop in the garage... I can now run the welder full bore in 220v 3 phase, while at the same time running heaters & compressors, 220v plasma cutters & anything else I can find to plug in a home without a problem, plus I redid the lighting as well... it's a better fab shop now for sure :smile (2): all just sucks up the weeks after weeks though & all just takes time...

far as stainless, wholey crap this is hard... man, welding a bead around this small ss pipe while not burning it, getting full penitration & a good weld is kinda like learning how to juggle meat cleavers while riding a unicycle while balancing a stack of books on your head... it sounds soo easy but actualy pulling it off well is extremely difficult

when I got my dynasty in september I thought I'd be welding up this ss pipe in a matter of weeks, probably the same way most guys that are new think there going to just pick up a torch & learn how to weld just like that... well this is way more challenging than I ever would have imagined, totally kicking my butt... I lost about a month to renovating & rewiring my garage to better facilitate this fabrication to finish building this car, but man, I can't tell you how many pieces of stainless steel I've had to cut, bevel, prep & weld so far to get to this point. before I started it would be hard to even imagine this could be so difficult & demanding... I can now see why it can take years to be proficient at this... man, it is not easy at all

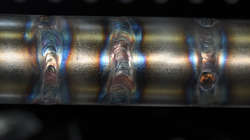

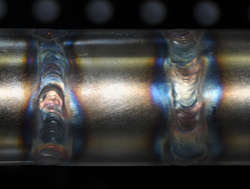

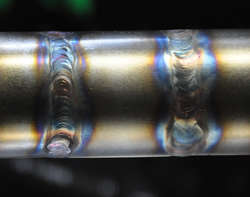

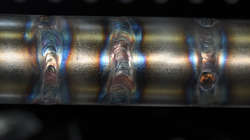

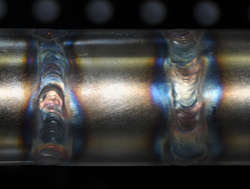

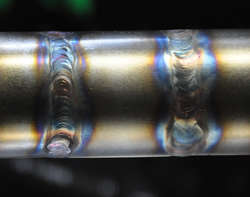

here are a few of my latest progress shots...

update? well, I've been practicing & practicing, but I've also had some problems along the way... the cold saw started to crap out & I had to wait for some parts which sucked up a few weeks down time, then I had to redo the whole fluid pumping setup again & built a custom stand to make it 100% contain the fluid without making a mess... working at home is not the same as working at the shop where mess & noise are a non issue

in the mean time I decided that my whole home garage workshop area was crap. one problem is, up until now I've only got one 15 amp 120v feed to the garage, AND the same circuit also fed my upstairs living room entertainment center too, so whenever I forgot to turn the heat off & started to tig the breaker would trip, sometimes just the startup of the compressor or my vacuum pump would even trip the breaker. breaker trips always lead to the same thing, try to find my way through the hallway to the panel in the dark, then wind up with all the clocks in all the entertainment & tv setup returning to blinking 12:00, this gets old pretty quick so I finally decided to get my electrician out to the house to see what can be done to add a new feed to the garage...

long story short this prompted me installing a new 100 amp 3 phase sub panel in my garage & completely redoing all new electrical & then redoing the whole garage itself, ripped all the old shelving & workbench & everything out & replaced everything, got a nice craftsman stainless steel worktop bench & kinda reorganized everything to make a better fabrication shop in the garage... I can now run the welder full bore in 220v 3 phase, while at the same time running heaters & compressors, 220v plasma cutters & anything else I can find to plug in a home without a problem, plus I redid the lighting as well... it's a better fab shop now for sure :smile (2): all just sucks up the weeks after weeks though & all just takes time...

far as stainless, wholey crap this is hard... man, welding a bead around this small ss pipe while not burning it, getting full penitration & a good weld is kinda like learning how to juggle meat cleavers while riding a unicycle while balancing a stack of books on your head... it sounds soo easy but actualy pulling it off well is extremely difficult

when I got my dynasty in september I thought I'd be welding up this ss pipe in a matter of weeks, probably the same way most guys that are new think there going to just pick up a torch & learn how to weld just like that... well this is way more challenging than I ever would have imagined, totally kicking my butt... I lost about a month to renovating & rewiring my garage to better facilitate this fabrication to finish building this car, but man, I can't tell you how many pieces of stainless steel I've had to cut, bevel, prep & weld so far to get to this point. before I started it would be hard to even imagine this could be so difficult & demanding... I can now see why it can take years to be proficient at this... man, it is not easy at all

here are a few of my latest progress shots...