You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

turbocad's custom fx

- Thread starter turbocad6

- Start date

ok, lots of practicing on the tig welding & lots of playing with the cold saw, this stainless steel is so tough to cut that even though the cold saw does a great job & gives a cut so fine that it looks like it's been milled it still does stress the saw quite a bit, winded up having issues with overheating the saw, at first I thought there was something wrong with it too but I've been back & forth with the manufacturer & it seems that it's just the bitch of dealing with cutting stainless steel.

so far I've been just chopping stainless into small sections & then just welding them back togeather, don't want to start on the actual header tubes until I really got it down pat enough to be able to do nice consistent welds that are good penetration but not penetrating enough to have the weld protrude into the tubing much at all... getting closer to good enough to start on rebuilding these headers... what a long tedious process this is...

also because of the backpurging this welding setup goes through argon like crazy, I'm emptying a 60 cubic ft bottle in just a few hours, I now called my gas supplier & ordered there extra large argon tank which is like 6 ft tall, to rent for a month or 2 till I finish this project... argon winds up being consumed at a pretty high rate BUT it makes all the difference in the world when it comes to the quality of the job & is absolutely necessary...

a few sample practice welds, nothing great or very consistent yet, but getting there, there already good enough as far as function but I want to get them good enough to look pro...

man, I'm really obsessed with getting these headers & this whole project to be a work of art at this point, haven't even begun to play much with the aluminum welding aspect of this project much yet but there is a whole lot of aluminum welding I'll have to be doing too so that's just around the bend after I master & conquer the stainless parts. I'm going to be building my own custom intercoolers & I plan to completely replace the whole radiator support with aluminum structure too. I'm at the point where I really don't care how long it takes or how much it costs, I want it to be what I want it to be. I just ordered a high end plasma cutter too, gotta complete the tool setup enough to be able to do all this fabrication 100% in house & 100% by me... if I get this thing running & tunned early enough in the winter then I'm seriously considering redoing the whole body custom & having the fx completed for the spring time with a new custom body as well... we'll see how that goes man, I miss my fx, but I won't finish it until it's good enough to be called done....

man, I miss my fx, but I won't finish it until it's good enough to be called done....

---------- Post added at 04:47 PM ---------- Previous post was at 04:40 PM ----------

oh, & the clean pipe at the top is the same as the bottom one but it has been cleaned with a blend of nitric acid & hydrofluoric acid specifically made for pickling & cleaning stainless steel, had to get this stuff shipped to me with hazmat shipping but it does a really nice job, I do plan on polishing the stainless headers after there finished

so far I've been just chopping stainless into small sections & then just welding them back togeather, don't want to start on the actual header tubes until I really got it down pat enough to be able to do nice consistent welds that are good penetration but not penetrating enough to have the weld protrude into the tubing much at all... getting closer to good enough to start on rebuilding these headers... what a long tedious process this is...

also because of the backpurging this welding setup goes through argon like crazy, I'm emptying a 60 cubic ft bottle in just a few hours, I now called my gas supplier & ordered there extra large argon tank which is like 6 ft tall, to rent for a month or 2 till I finish this project... argon winds up being consumed at a pretty high rate BUT it makes all the difference in the world when it comes to the quality of the job & is absolutely necessary...

a few sample practice welds, nothing great or very consistent yet, but getting there, there already good enough as far as function but I want to get them good enough to look pro...

man, I'm really obsessed with getting these headers & this whole project to be a work of art at this point, haven't even begun to play much with the aluminum welding aspect of this project much yet but there is a whole lot of aluminum welding I'll have to be doing too so that's just around the bend after I master & conquer the stainless parts. I'm going to be building my own custom intercoolers & I plan to completely replace the whole radiator support with aluminum structure too. I'm at the point where I really don't care how long it takes or how much it costs, I want it to be what I want it to be. I just ordered a high end plasma cutter too, gotta complete the tool setup enough to be able to do all this fabrication 100% in house & 100% by me... if I get this thing running & tunned early enough in the winter then I'm seriously considering redoing the whole body custom & having the fx completed for the spring time with a new custom body as well... we'll see how that goes

---------- Post added at 04:47 PM ---------- Previous post was at 04:40 PM ----------

oh, & the clean pipe at the top is the same as the bottom one but it has been cleaned with a blend of nitric acid & hydrofluoric acid specifically made for pickling & cleaning stainless steel, had to get this stuff shipped to me with hazmat shipping but it does a really nice job, I do plan on polishing the stainless headers after there finished

sick work john.. you are crazy. Plasma cutter? oh man.. this is going to be one heck of a build thread haha

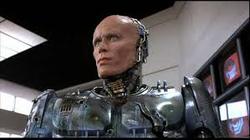

i envision your work to look like this in no time

:smile (2):

What is that?

What is that?

sexy welding on a x6m

I still need more welding practice

I got my intercooler cores friday, custom sized to my spec's. building the intercoolers with vertical cores, there much more efficient & flow better too, looking for the least amount of pressure drop across the core, this can all add up to the difference between making 400hp at 11 psi or making the same 400hp at only 8 psi, I'm trying for as efficient as possible.

cores are only 2.25" deep but these cores are rated at 625 cfm's each which is enough airflow for over 850hp, less depth add up to more cool air flow through the core, especially with nothing blocking the rear exit of airflow, the narrower core also allowed me to maximize the size of the face of the intercooler without adding too much excess air volume to the overall cold side piping. this combined with my real short piping should give awesome throttle response, especially still having the higher stock compression ratio it should be almost as strong & peppy as a regular HR engine, just get better as boost comes on.

most turbo installs, while making more power up stairs, actually loose some power & drivability to a certain extent when not in boost, the average part throttle response of a turbo car before boost is the equivalent of taking an intercooler & a bunch of extra length of pipework & hooking that all up to your normally aspirated fx with a slow spinning turbo that is more of a restriction than a help at that point, imagine what that does to your throttle response, well, before a turbo car reaches actual boost it's really under this same condition of restrictions, this adds to turbo lag & sluggish part throttle, then when it reaches boost it comes on as all gang busters with a big surge of power, not so linear or smooth & progressive. I'm trying to make mine smooth & progressive & peppy even when not in boost which really when you think about it is probably like 90% of the time on a street car. this is one of the reasons I wanted to build my own kit rather than using an off the shelf kit, so I can design & lay out for higher efficiency from the optimized intercoolers & short tubing & the equal length tubular headers... it should work real good, in theory anyway :nerd (2):

I got my intercooler cores friday, custom sized to my spec's. building the intercoolers with vertical cores, there much more efficient & flow better too, looking for the least amount of pressure drop across the core, this can all add up to the difference between making 400hp at 11 psi or making the same 400hp at only 8 psi, I'm trying for as efficient as possible.

cores are only 2.25" deep but these cores are rated at 625 cfm's each which is enough airflow for over 850hp, less depth add up to more cool air flow through the core, especially with nothing blocking the rear exit of airflow, the narrower core also allowed me to maximize the size of the face of the intercooler without adding too much excess air volume to the overall cold side piping. this combined with my real short piping should give awesome throttle response, especially still having the higher stock compression ratio it should be almost as strong & peppy as a regular HR engine, just get better as boost comes on.

most turbo installs, while making more power up stairs, actually loose some power & drivability to a certain extent when not in boost, the average part throttle response of a turbo car before boost is the equivalent of taking an intercooler & a bunch of extra length of pipework & hooking that all up to your normally aspirated fx with a slow spinning turbo that is more of a restriction than a help at that point, imagine what that does to your throttle response, well, before a turbo car reaches actual boost it's really under this same condition of restrictions, this adds to turbo lag & sluggish part throttle, then when it reaches boost it comes on as all gang busters with a big surge of power, not so linear or smooth & progressive. I'm trying to make mine smooth & progressive & peppy even when not in boost which really when you think about it is probably like 90% of the time on a street car. this is one of the reasons I wanted to build my own kit rather than using an off the shelf kit, so I can design & lay out for higher efficiency from the optimized intercoolers & short tubing & the equal length tubular headers... it should work real good, in theory anyway :nerd (2):

John with those intercooler.. You should look into the from bumper design (theproducer) came up with.. The one that looks like the cayenne's bumper.. It'll go with your setting perfectly.

I know you are going to roll all "original style" John but that's a good call, the Porsche style vents would look great and add a lot of breathable area directly to the intercoolers.

hey, just realized I never answered this here but yeah, I wouldn't want a bumper that looks distinctively like a porsche design really, def gonna be custom & unique to this fx.

anyway, another update to my ongoing saga of building my own stainless headers... honestly I gotta say, that if I had really known then all that I know now about building stainless steel headers before starting this project, then I probably would have just settled for a JWTT setup. not because it would have been better, but because it was just insane for me to have to become a stainless welding expert here & because it was just insane the amount of time & money I'm winding up investing in this... at this point I've invested as much in tooling alone to have almost paid for a whole JWTT setup as crazy as that may sound, but, live & learn... in the end I don't think I'll be sorry though because I do fully expect it to be awesome & I do believe that it will be better, it will def be one of a kind & I will have learned quite a bit that will go a long way towards making any other turbo setup I build that much more doable...

what I have been researching & learning about stainless steel welding is how susceptible to damage stainless steel is from the welding process. when you see stainless headers crack near the weld it is because the stainless was overheated when it was welded & this causes carbide precipitation, this break down ruins the properties of the stainless steel that is what makes stainless so good to begin with. from everything I have been learning I'm now willing to say that in my opinion I think way more than half of even so called professionals who weld stainless steel for high performance use really are not doing it 100% correct, & this is why you will see so many failures, cracks & worse. it is tricky to be able to weld stainless steel without putting too much heat into it. many guys think that you just weld it & as long as it welds well then it's fine, but this is not really the case, welding stainless & putting too much heat into it will cause inevitable failure down the road & I've went this far already so now I'm looking to really get good enough to do not just adequate welds but more to be able to do "good" proper welds in this stainless steel.

I've been reading a lot & talking to a lot of professionals in the field of welding, not so much just performance guys, because I don't believe the majority of them are really at the top of there game, but I've been talking more to professional welders & pipe fitters, guys that are certified to weld stainless steel in critical applications where there is no room for error, guys that do whats called "sanitary welding" in stainless piping for the food industry & commercial/industrial stuff. this kind of welding is way more critical than just a set of turbo headers. these guys are subject to X-ray inspections & analysis in situations where any less than perfect is just not acceptable & a whole lot of corporate $$ is on the line. most performance guys are amateurs compared to this level of weldors & the more "correct" the welds are done the more longevity & durability of the finished project. I'm not going to say there are no performance guys that are this good, but I will say that they are the exception rather than the norm.

so anyway, what I have been learning is that the reason the stainless weld el's are beveled at the edges is to allow full penetration for a sanitary weld without having to use excessive heat to get this, a sanitary weld that will pass X-ray inspection must have full penetration with no voids & no crevices at all, & the metal cannot be heated past the point of introducing carbide precipitation. many will believe this level of perfection is not necessary for something like headers, but if the welds are truly done to this standard then the areas adjacent the welds will be no more likely to crack than anywhere else really & the job will just be that much better and the bottom line is that the headers will not crack or fail prematurely. this has nothing o do with the "look" of the weld, just because a weld looks pretty does not mean that it was done 100% correctly

so, to that end I have had to step my game up a bit here, I am now learning to weld stainless correctly & in doing so it has become necessary for me to be able to bevel all my edges correctly too. I tried to do it manually by just grinding but the results are just too inconsistent. any inconsistency in the butt joint will translate to an inconsistency in the weld penetration, so I had to come up with a way to get perfect beveled edges just like the factory edges on the weld el's... I looked into buying a pipe beveler but these are pretty specialized tools that cost a fortune, so I decided I have to build it myself... here is how I did it

I bought a pneumatic die grinder & I made a base from 1/8" steel plate, I then welded together what you see here, I used a piece of cold rolled sheet steel as a shim plate for final positioning & a smooth surface to rotate the pipe on. the results are perfect. I can now get a perfect beveled edge that is an exact match for the factory beveled edges on the weld elbows. this has now made a very big difference to my final welded seems & I'm now pretty close to really being able to start building actual headers:err:

this is what my bevel looks like compared to the factory bevel on the weld el, exactly the same

and here is what a proper butted seem looks like prepared to be welded

this is what the inside of a sanitary weld looks like

all of this research & learning & tooling development is really increasing the amount of time it's taking me to get this done, but as I said before, if it's worth doing at all then it's worth doing right... later I'll show you guys the problem I've had with my cold saw & what I had to wind up building for that too:confused.: but for now I'm going back to practicing my welds:tonguey:

anyway, another update to my ongoing saga of building my own stainless headers... honestly I gotta say, that if I had really known then all that I know now about building stainless steel headers before starting this project, then I probably would have just settled for a JWTT setup. not because it would have been better, but because it was just insane for me to have to become a stainless welding expert here & because it was just insane the amount of time & money I'm winding up investing in this... at this point I've invested as much in tooling alone to have almost paid for a whole JWTT setup as crazy as that may sound, but, live & learn... in the end I don't think I'll be sorry though because I do fully expect it to be awesome & I do believe that it will be better, it will def be one of a kind & I will have learned quite a bit that will go a long way towards making any other turbo setup I build that much more doable...

what I have been researching & learning about stainless steel welding is how susceptible to damage stainless steel is from the welding process. when you see stainless headers crack near the weld it is because the stainless was overheated when it was welded & this causes carbide precipitation, this break down ruins the properties of the stainless steel that is what makes stainless so good to begin with. from everything I have been learning I'm now willing to say that in my opinion I think way more than half of even so called professionals who weld stainless steel for high performance use really are not doing it 100% correct, & this is why you will see so many failures, cracks & worse. it is tricky to be able to weld stainless steel without putting too much heat into it. many guys think that you just weld it & as long as it welds well then it's fine, but this is not really the case, welding stainless & putting too much heat into it will cause inevitable failure down the road & I've went this far already so now I'm looking to really get good enough to do not just adequate welds but more to be able to do "good" proper welds in this stainless steel.

I've been reading a lot & talking to a lot of professionals in the field of welding, not so much just performance guys, because I don't believe the majority of them are really at the top of there game, but I've been talking more to professional welders & pipe fitters, guys that are certified to weld stainless steel in critical applications where there is no room for error, guys that do whats called "sanitary welding" in stainless piping for the food industry & commercial/industrial stuff. this kind of welding is way more critical than just a set of turbo headers. these guys are subject to X-ray inspections & analysis in situations where any less than perfect is just not acceptable & a whole lot of corporate $$ is on the line. most performance guys are amateurs compared to this level of weldors & the more "correct" the welds are done the more longevity & durability of the finished project. I'm not going to say there are no performance guys that are this good, but I will say that they are the exception rather than the norm.

so anyway, what I have been learning is that the reason the stainless weld el's are beveled at the edges is to allow full penetration for a sanitary weld without having to use excessive heat to get this, a sanitary weld that will pass X-ray inspection must have full penetration with no voids & no crevices at all, & the metal cannot be heated past the point of introducing carbide precipitation. many will believe this level of perfection is not necessary for something like headers, but if the welds are truly done to this standard then the areas adjacent the welds will be no more likely to crack than anywhere else really & the job will just be that much better and the bottom line is that the headers will not crack or fail prematurely. this has nothing o do with the "look" of the weld, just because a weld looks pretty does not mean that it was done 100% correctly

so, to that end I have had to step my game up a bit here, I am now learning to weld stainless correctly & in doing so it has become necessary for me to be able to bevel all my edges correctly too. I tried to do it manually by just grinding but the results are just too inconsistent. any inconsistency in the butt joint will translate to an inconsistency in the weld penetration, so I had to come up with a way to get perfect beveled edges just like the factory edges on the weld el's... I looked into buying a pipe beveler but these are pretty specialized tools that cost a fortune, so I decided I have to build it myself... here is how I did it

I bought a pneumatic die grinder & I made a base from 1/8" steel plate, I then welded together what you see here, I used a piece of cold rolled sheet steel as a shim plate for final positioning & a smooth surface to rotate the pipe on. the results are perfect. I can now get a perfect beveled edge that is an exact match for the factory beveled edges on the weld elbows. this has now made a very big difference to my final welded seems & I'm now pretty close to really being able to start building actual headers:err:

this is what my bevel looks like compared to the factory bevel on the weld el, exactly the same

and here is what a proper butted seem looks like prepared to be welded

this is what the inside of a sanitary weld looks like

all of this research & learning & tooling development is really increasing the amount of time it's taking me to get this done, but as I said before, if it's worth doing at all then it's worth doing right... later I'll show you guys the problem I've had with my cold saw & what I had to wind up building for that too:confused.: but for now I'm going back to practicing my welds:tonguey:

Last edited:

wow john that's a really cool little base you made fir it, and your welds are looking much better with every new invention you create! what i think is funny though every tool you buy you have to modify it or create something for it to work properly. lol

- Car

- 2003 FX35T

- Name

- Brad

Yeah John, I came to the same conclusion after crossing the $12K mark on my build. We touched on cost before both of us started the FI work and I really think both of us were optimistic. The JWT TT is by far the most bang for the buck. I've even considered a second FX, just for the JWT!

Unfortunately you/we are already committed to a particular course and would have to spend a bunch more to change directions.

So maybe here's a way to cover your time and effort. Make two sets of everything, so after finishing your car you have a single completed kit you can ship off to China to be copied for mass production runs.

Unfortunately you/we are already committed to a particular course and would have to spend a bunch more to change directions.

So maybe here's a way to cover your time and effort. Make two sets of everything, so after finishing your car you have a single completed kit you can ship off to China to be copied for mass production runs.

I think my own biggest problem so far was in me severely underestimating the amount of skill necessary for a really good quality weld job on stainless steel & having faith in someone else to do it for me. I had so many other obstacles to think about with the HR swap & all the other interface stuff that should have been hard. I just assumed the welding & overall building of the headers was the trivial part. it turned into the hardest part of the whole job. even the cutting of the stainless steel turned into a big project, I couldn't possibly redo them the way I did the first time, the abrasive chop saw was a nightmare

the JWTT uses cast manifolds & has none of the issues of particles damaging a turbo. there are a whole lot of things I can say about why I decided the JWTT was not good enough & I'm still not going to say I'd prefer that over what I'm building, but if I realized the total cost of everything involved then I may have just settled, but then again I had other complications like the fact that I'm using an HR motor too, not a DE. I would have had to go with something like GTM's twin setup. in the end I think my setup will be better though, which is why I decided to build it in the first place, it's just kicking my ass here though :nerd (2):

the stupidest trivial stuff has turned into such a pain in the ass. even the friggin saw I bought for cutting this stainless steel. the people I talked to about cutting this stainless all told me it wouldn't work on weld el's, general consensus was that I should ue a band saw. there's no way to clamp them adequately for a cold saw & it wouldn't work, but even that I was able to solve easily with a just building a custom jig. what's supposed to be hard really isn't, so now the saw should just work right? I don't know why it just don't work out that way though.

this saw, from day one the fluid pump didn't work at all. took weeks to get the thing truck freighted to me on a 175 lb pallet, can't just return it & even then, I still need to get the job done, so I rigged up the little coolant pump & filter & it kinda worked for a bit, but it didn't work well for long. particles would clog up the filter quickly & the pump would die little buy little & I had to keep stopping, cleaning the filter & then starting again, still kinda sucked

so now what? I'm left with no choice but to build a proper filtered coolant system for the damn saw. ahhh, another project within the project:confused.:

I winded up going to a marina & picking up a good commercial Jabsco live well pump. it uses a flexible impeller in a brass housing so even debris in the fluid will not be an issue at all with this pump. it uses an 8 amp motor. overkill, but overkill is good, much better than inadequate.

I also searched everywhere & winded up finding a perfect thing to use for the filter. I found a whole house filtration system thing that's designed to be used on a main water feed to a house from the street, it's made by whirlpool. it has a 2 quart clear reservoir which is ideal & the filter is huge so it don't clog up at all, I can get hundreds of cuts before I have to think about cleaning the filter, the fluid would need to be changed before this filter clogs, it can hold a ton of metal shavings no problem & it uses a 30 micron filter element. I built a new drain tray instead of the reservoir tray tank setup that the saw originally used, my smaller tray just collects all fluid & drains it straight into the new reservoir tank which is my filter assy. heres a few pictures of this

this was the first version

and the redo

here it is running. I'm using an inline valve to regulate flow. I have to restrict the pump a bit or it'll empty the reservoir out real quick before the fluid can drain back to replenish the supply. when that happens it starts sucking air. this makes the fluid foam up & it don't cut well when it's aerated like that. I just dial it back to the right flow to keep ~1/3 of the tank full & it works perfect.

now the fluid system is kick ass & not an issue at all any more. I switched to a 150 tooth blade & the saw is now really working good, that and the beveler I made & now finally these cuts & prep for weld is just easy. now just gotta perfect my weld technique enough, getting closer though...

after I finish my setup & prove it to work well I will build another, the way I figure it, everything that I'm doing on my fx should also bolt right up to a second gen with an HR motor. that will be my next car in a few years & the plan right now is to build a second setup & collect the parts for another setup & then I'll bolt the twin turbo setup on it as soon as I get it :smile (2):

the JWTT uses cast manifolds & has none of the issues of particles damaging a turbo. there are a whole lot of things I can say about why I decided the JWTT was not good enough & I'm still not going to say I'd prefer that over what I'm building, but if I realized the total cost of everything involved then I may have just settled, but then again I had other complications like the fact that I'm using an HR motor too, not a DE. I would have had to go with something like GTM's twin setup. in the end I think my setup will be better though, which is why I decided to build it in the first place, it's just kicking my ass here though :nerd (2):

the stupidest trivial stuff has turned into such a pain in the ass. even the friggin saw I bought for cutting this stainless steel. the people I talked to about cutting this stainless all told me it wouldn't work on weld el's, general consensus was that I should ue a band saw. there's no way to clamp them adequately for a cold saw & it wouldn't work, but even that I was able to solve easily with a just building a custom jig. what's supposed to be hard really isn't, so now the saw should just work right? I don't know why it just don't work out that way though.

this saw, from day one the fluid pump didn't work at all. took weeks to get the thing truck freighted to me on a 175 lb pallet, can't just return it & even then, I still need to get the job done, so I rigged up the little coolant pump & filter & it kinda worked for a bit, but it didn't work well for long. particles would clog up the filter quickly & the pump would die little buy little & I had to keep stopping, cleaning the filter & then starting again, still kinda sucked

so now what? I'm left with no choice but to build a proper filtered coolant system for the damn saw. ahhh, another project within the project:confused.:

I winded up going to a marina & picking up a good commercial Jabsco live well pump. it uses a flexible impeller in a brass housing so even debris in the fluid will not be an issue at all with this pump. it uses an 8 amp motor. overkill, but overkill is good, much better than inadequate.

I also searched everywhere & winded up finding a perfect thing to use for the filter. I found a whole house filtration system thing that's designed to be used on a main water feed to a house from the street, it's made by whirlpool. it has a 2 quart clear reservoir which is ideal & the filter is huge so it don't clog up at all, I can get hundreds of cuts before I have to think about cleaning the filter, the fluid would need to be changed before this filter clogs, it can hold a ton of metal shavings no problem & it uses a 30 micron filter element. I built a new drain tray instead of the reservoir tray tank setup that the saw originally used, my smaller tray just collects all fluid & drains it straight into the new reservoir tank which is my filter assy. heres a few pictures of this

this was the first version

and the redo

here it is running. I'm using an inline valve to regulate flow. I have to restrict the pump a bit or it'll empty the reservoir out real quick before the fluid can drain back to replenish the supply. when that happens it starts sucking air. this makes the fluid foam up & it don't cut well when it's aerated like that. I just dial it back to the right flow to keep ~1/3 of the tank full & it works perfect.

now the fluid system is kick ass & not an issue at all any more. I switched to a 150 tooth blade & the saw is now really working good, that and the beveler I made & now finally these cuts & prep for weld is just easy. now just gotta perfect my weld technique enough, getting closer though...

after I finish my setup & prove it to work well I will build another, the way I figure it, everything that I'm doing on my fx should also bolt right up to a second gen with an HR motor. that will be my next car in a few years & the plan right now is to build a second setup & collect the parts for another setup & then I'll bolt the twin turbo setup on it as soon as I get it :smile (2):

- Car

- 2003 FX35T

- Name

- Brad

I thought I was loony, you're crazy!!! You have a lot of gear now. hahahah :eek.:

+1 You ARE crazy.

But I wish I had the money, time & space to do exactly what you are doing. I'd even consider staying in NY for a month just to work on my FX in your shop! For a modest space rental fee, of course...

+1 You ARE crazy.

But I wish I had the money, time & space to do exactly what you are doing. I'd even consider staying in NY for a month just to work on my FX in your shop! For a modest space rental fee, of course...

think you may want to buy a one way ticket :tongue (2):

a-m-a-z-i-n-g, john. cant wait for the day turbocad motorsports produces a drop in tt engine

Share: