oh man, first this thread, then the headlights from hell thread on top of it :tongue (2):

those headlights were just a nightmare, never was able to get many of them done, they were just not coming out how I wanted them. the clear corners were problems, the LEDS sucked... just too many things weren't as good as I wanted them to be. then when I started this turbo build I couldn't continue with them at all. never had time to finish playing with those lights... when I finish my FX I'll go back to try finishing up whatever headlights I have around in pieces

...

here with the fx I'm getting closer. so hard to find extra time.

I also winded up buying another car because I just couldn't take it any more

. the fx went from being just months, to then over a year & now it looks like it will probably be running again for it's 2nd year anniversary if I'm lucky, so I really needed to buy a decent car for the weekends & family stuff. I'll put a few pics up in a bit, but this too unfortunately winded up taking away time from the FX... I really didn't want to do much custom work to the new car, but of course knowing me then you'll know that I just can't leave certain things alone no matter how hard I try, so I had to do some things at least...

like this fx, the first primary required mods I did on the new car are just a paint job, a set of decent wheels with new tires and of course the most important thing, a computer of some sort in the dash:wink (2): just about finishing off the install on the new car, wheels & paint already done, then straight back to the fx again...

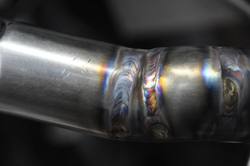

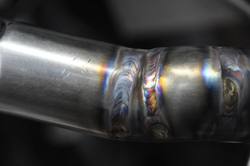

some updated pictures of progress since my last update here, second header fitup is also done & the headers are more than half way welded.

I was having problems while welding these pipes & eventually it winded up leading to my developing a header tig welding station thing. it's basically an adjustable seat & pivoting arm thing. the problem was, as I rotated the pipe & changed angles to do the different parts of the different welds the pipe would wind up being either too high or too low. the key to consistent good welds on these things is being stable & comfortable with good hand position & stability... here I adjust to the right position that I can rest my forearm on the seat back lined up for each weld.. this adjustable work station really helps... but it also really added more work & more time but I guess I'm getting used to that by now :tongue (2):...

then, also as I'm getting ready to weld all the tubes together into one solid header, I now need to purge all 3 pipes at the same time, plus even though my articulating arm's clamp head also feeds an argon purge to the pipe there are times I need to reverse the flow too, so I built a whole purge valve control manifold into the tig station too